Precision Laser Cutting Services Explained

- Thomas Precision Welding

- Sep 30

- 4 min read

When it comes to custom metalwork, welding, and fabrication, precision is everything. We understand the importance of delivering flawless results that meet exact specifications. That’s why laser cutting precision plays a crucial role in modern manufacturing and fabrication processes. Today, we’ll dive deep into the world of laser cutting, exploring how it works, why it’s so precise, and how it can benefit your projects.

Understanding Laser Cutting Precision: What Sets It Apart?

Laser cutting precision is not just a buzzword; it’s a defining feature that separates high-quality fabrication from the rest. At its core, laser cutting uses a focused beam of light to cut through materials with incredible accuracy. Unlike traditional cutting methods, lasers can create intricate shapes and fine details without compromising the material’s integrity.

The precision comes from several factors:

Beam Focus: The laser beam is concentrated to a tiny spot, often less than 0.1 mm in diameter.

Computer Control: CNC (Computer Numerical Control) systems guide the laser, ensuring exact movements and repeatability.

Material Interaction: The laser’s heat melts or vaporizes the material cleanly, leaving smooth edges.

This combination allows us to produce parts with tight tolerances, minimal waste, and consistent quality. Whether you need thin sheet metal or thicker plates, laser cutting precision ensures your designs come to life exactly as intended.

Laser cutting machine delivering precise cuts on metal sheets

How Laser Cutting Precision Benefits Your Projects

Precision in laser cutting translates directly into better outcomes for your projects. Here’s how:

Reduced Material Waste: The narrow kerf (cut width) means less scrap material, saving costs.

Faster Turnaround: Accurate cuts reduce the need for secondary finishing or rework.

Complex Designs Made Easy: Intricate patterns and small holes are achievable without compromising strength.

Consistent Quality: CNC control ensures every piece matches the design perfectly, even in large production runs.

Versatility: Laser cutting works on various metals like steel, aluminum, stainless steel, and more.

For example, if you’re fabricating custom brackets or structural components, laser cutting precision guarantees that bolt holes align perfectly and edges fit seamlessly. This precision reduces assembly time and improves the overall durability of the final product.

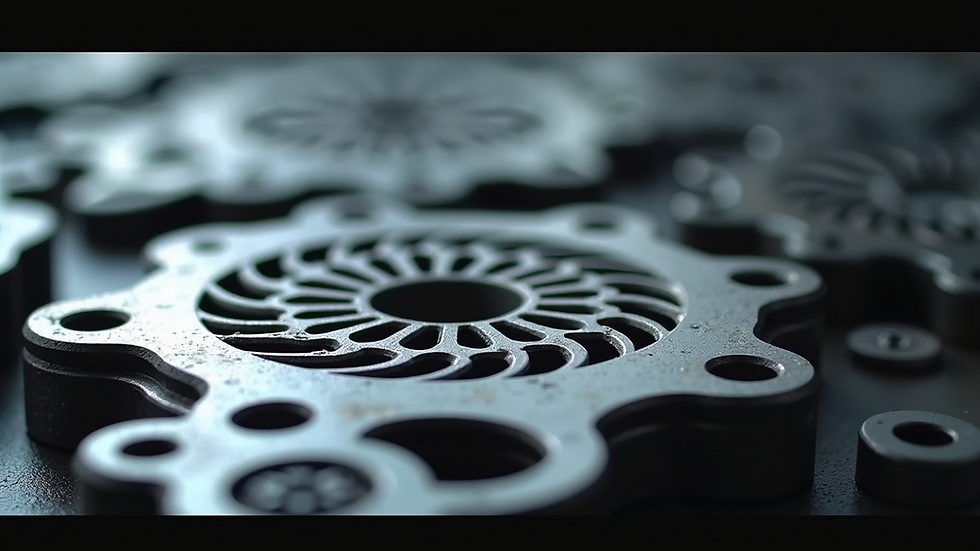

Intricate laser-cut metal parts showcasing clean and precise edges

What is the hour rate for laser cutting machine?

Understanding the cost structure is essential when planning your fabrication budget. The hour rate for a laser cutting machine varies depending on several factors:

Material Type and Thickness: Thicker or harder materials require more power and time.

Machine Type and Size: Larger, more advanced machines typically have higher hourly rates.

Setup and Programming Time: Complex jobs may need additional preparation.

Volume of Work: Bulk orders often reduce the per-hour or per-piece cost.

On average, laser cutting machines can range from $75 to $150 per hour. However, this rate often includes not just the machine operation but also programming, setup, and quality checks. When you work with a trusted provider like Thomas Precision Welding, you get transparent pricing tailored to your project’s specifics.

To optimize costs, consider:

Grouping similar parts in one run to reduce setup time.

Providing clear, finalized designs to avoid revisions.

Choosing materials that balance performance and cost.

By understanding these factors, you can better plan your project and avoid surprises.

Exploring the Range of Materials and Thicknesses for Laser Cutting

Laser cutting precision is effective across a wide range of materials, but knowing the limits helps in selecting the right approach. Common materials include:

Mild Steel: Up to 1 inch thick, ideal for structural components.

Stainless Steel: Typically up to 0.5 inch thick, used for corrosion-resistant parts.

Aluminum: Up to 0.25 inch thick, lightweight and versatile.

Brass and Copper: Thinner sheets due to reflectivity challenges.

Each material reacts differently to laser cutting. For instance, aluminum’s reflectivity requires specialized lasers or coatings to achieve clean cuts. Thickness also affects speed and edge quality. Thicker materials may need slower cutting speeds or multiple passes.

When precision is critical, we recommend discussing your material choice with your laser cutting provider. They can advise on the best laser type and settings to ensure optimal results.

Various metal sheets prepared for laser cutting, showcasing material diversity

Why Choose Thomas Precision Welding for Your Laser Cutting Needs?

At Thomas Precision Welding, we pride ourselves on delivering unmatched precision and quality. Our state-of-the-art laser cutting equipment, combined with skilled operators, ensures your projects are completed on time and to exact specifications. We serve clients across Nevada, California, and Arizona, handling everything from small custom jobs to large-scale fabrication.

Here’s what sets us apart:

Full-Service Solutions: Beyond laser cutting, we offer welding, fabrication, and mechanical contracting.

Experienced Team: Our professionals understand the nuances of metalwork and fabrication.

Customer Focus: We prioritize your satisfaction and project deadlines.

Advanced Technology: We invest in the latest laser cutting machines for superior precision.

By choosing us, you gain a partner committed to excellence and reliability. Whether you need a single prototype or a production run, we tailor our services to meet your needs.

For more information on our precision laser cutting services, visit our website or contact us directly. We’re here to help you bring your designs to life with confidence.

Maximizing the Benefits of Laser Cutting Precision in Your Projects

To get the most out of laser cutting precision, consider these actionable tips:

Design for Laser Cutting: Use vector-based CAD files and avoid unnecessary complexity.

Communicate Clearly: Provide detailed specifications and tolerances upfront.

Plan for Finishing: Although laser cuts are clean, some projects may require deburring or coating.

Leverage Prototyping: Test designs with small runs before full production.

Maintain Flexibility: Be open to material or design adjustments based on laser cutting capabilities.

By following these guidelines, you can reduce costs, improve quality, and speed up your project timeline.

Laser cutting precision is a game-changer in metal fabrication. It offers unmatched accuracy, efficiency, and versatility that can elevate your projects to the next level. With the right partner and approach, you can harness the full potential of this technology to achieve outstanding results every time.

Comments